Friends who know SOKOYO know that SOKOYO Solar has been able to complete the independent production of the five major components of solar street lights many years ago. As one of the components, the light pole, like an unknown young man, supports the normal operation of the entire solar system with diligence and firmness. But we have never focused on it, here is a column for it, about its type, craftsmanship and quality.

1. Types of light poles

- Concrete poles: very common 20 years ago, mainly attached to power facilities, but they are too bulky, have high transportation costs, unstable foundations and prone to accidents, and have basically been eliminated now.

-Glass fiber street light pole: Inorganic non-metallic material, good performance and variety, heat resistance, insulation, corrosion resistance are very good, but poor wear resistance, relatively brittle, so the market is not used much.

-Aluminum alloy light pole: made of high-strength aluminum alloy, high strength, super corrosion resistance, very beautiful, high-grade, high durability, wide application range, good decorative effect, has been widely used in the street lamp industry application.

-Stainless steel light pole: it is the best among steel materials, second only to titanium alloy, it has the performance of chemical corrosion resistance and electrochemical corrosion resistance, but the cost is high.

-Iron street light poles are made of Q235 steel, and are treated with hot-dip galvanizing for anti-corrosion treatment, with a service life of up to 30 years. The cost is low and the cost performance is high. At present, this kind of light pole is mostly used in our country.

-High pole light refers to a lighting device composed of a steel tapered light pole above 15M and a high-power combined light frame. It is composed of a lamp holder, internal lighting appliances, rod body and basic parts. The shape of the lamp holder is based on user requirements, surrounding environment, and lighting needs. Depending on the specific conditions, the internal lamps are mostly composed of floodlights and floodlights, with a lighting radius of 60M. The light pole is polygonal, generally dodecagonal, hexagonal, and octadecagonal, with a height of 15M-40M, generally three to four sections, and the depth of each section is 1-1.5M.

Places of use: freight yards, highways, stadiums, overpasses, city squares, docks, stations, etc.

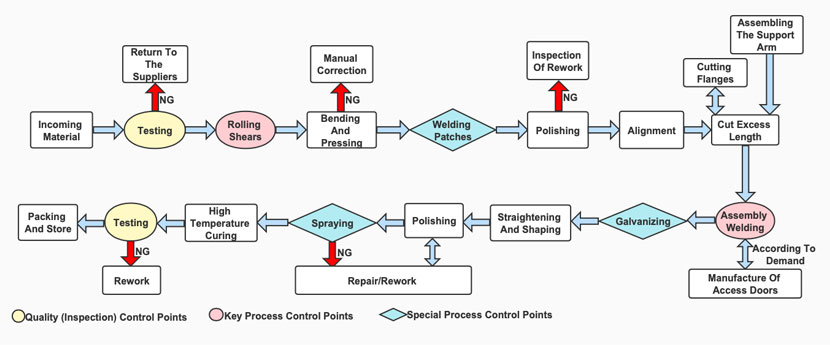

2. The production process of light poles

Every link will be inspected in accordance with the "Lamp Pole Process Inspection Standard", strictly paying attention to quality control points, key process control points and special process control points, so that each pole can safely and stably withstand the test of different levels of wind speed.

After the expansion of the new factory, the production area of the rod workshop has reached 15,000 square meters, and 10 aerial cranes, 1 laser cutting machine, 1 automatic rod rolling machine, and several automatic welding machines have been introduced. With the comprehensive strength of hardware and software Make you satisfied.

For more member cases and technical solution consultation, please contact us.